umgaqo wokusebenza

Xa isihluzo esilaminethiweyo sisebenza ngokuqhelekileyo, amanzi aqukuqela kwisihluzo esilaminethiweyo, esebenzisa udonga kunye nomjelo ukuqokelela nokuthintela inkunkuma.Icandelo elingaphakathi elihlanganisiweyo le-groove libonelela nge-filtration ye-three-dimensional efana naleyo iveliswa kwisanti kunye nezihluzo zegrabile.Ke ngoko, ukusebenza kakuhle kokucoca kwayo kuphezulu kakhulu.Xa isihluzo se-laminated sisebenza ngokufanelekileyo, isihluzo se-laminated sitshixiwe.Isihluzi sikwanokushenxiswa okanye sigungxulwe ngokuzenzekelayo.Xa ukuhlamba ngesandla kuyadingeka, susa into yokucoca, ukhulule i-nut yoxinzelelo, kwaye uhlambulule ngamanzi.Ngexesha elifanayo, linamandla kunokugcinwa kwe-net filter yokungcola, ngoko ke inani lokuhlamba lincinci, ukuhlamba ukusetyenziswa kwamanzi kuncinci.Nangona kunjalo, ishidi elaminethiweyo kufuneka likhululeke ngokwalo xa lihlamba ngokuzenzekelayo.Ngenxa yempembelelo yezinto eziphilayo kunye nokungcola kweekhemikhali kumzimba wamanzi, amanye amashiti ane-laminated ahlala enamathele kunye kwaye akulula ukuba ahlanjwe kakuhle.

Inkqubo yokusebenza

Xa isihluzo esilaminethiweyo sisebenza ngokuqhelekileyo, amanzi aqukuqela kwisihluzo esilaminethiweyo, esebenzisa udonga kunye nomjelo ukuqokelela nokuthintela inkunkuma.Icandelo elingaphakathi elihlanganisiweyo le-groove libonelela nge-filtration ye-three-dimensional efana naleyo iveliswa kwisanti kunye nezihluzo zegrabile.Ke ngoko, ukusebenza kakuhle kokucoca kwayo kuphezulu kakhulu.Xa isihluzo se-laminated sisebenza ngokufanelekileyo, isihluzo se-laminated sitshixiwe.Isihluzi sikwanokushenxiswa okanye sigungxulwe ngokuzenzekelayo.Xa ukuhlamba ngesandla kuyadingeka, susa into yokucoca, ukhulule i-nut yoxinzelelo, kwaye uhlambulule ngamanzi.Ngexesha elifanayo, linamandla kunokugcinwa kwe-net filter yokungcola, ngoko ke inani lokuhlamba lincinci, ukuhlamba ukusetyenziswa kwamanzi kuncinci.Nangona kunjalo, ishidi elaminethiweyo kufuneka likhululeke ngokwalo xa lihlamba ngokuzenzekelayo.Ngenxa yempembelelo yezinto eziphilayo kunye nokungcola kweekhemikhali kumzimba wamanzi, amanye amashiti ane-laminated ahlala enamathele kunye kwaye akulula ukuba ahlanjwe kakuhle.

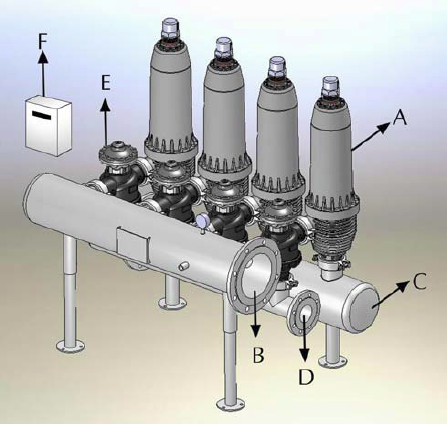

Uhluzo

Ukuhamba kwamanzi kwindawo yokungena kwisihluzi, isitaki sokucoca sixinzelelwe ngokuqinileyo kunye nesitaki sokucoca phantsi kwesenzo samandla entwasahlobo kunye namandla oxinzelelo lwe-hydraulic, amasuntswana okungcola ayabanjwa kwindawo yokuwela isitaki, amanzi ahluziweyo aphuma kumjelo ophambili we icebo lokucoca, ngeli xesha ivalve yendlela enye diaphragm ivuliwe.

Ukuhlamba umqolo

Xa umlinganiselo othile woxinzelelo ufikeleleke, okanye ixesha elimiselweyo, inkqubo ingena ngokuzenzekelayo kwi-backwash state, umlawuli ulawula i-valve ukuguqula indlela yokuhamba kwamanzi, i-diaphragm yendlela enye ephantsi kwesihlunu ivala umjelo oyintloko, ijelo lokuhlamba umva lingena kumaqela amane ejelo lombhobho, kwaye ijelo lombhobho elidityaniswe negumbi lepiston loxinzelelo lwamanzi liyenyuka, ipiston ihambela phezulu ukoyisa uxinzelelo lwasentwasahlobo kwisitaki, kwaye ikhuphe isithuba sepiston phezulu kwesipaki.Ngelo xesha, amanzi okuhlamba umva atshizwa ngesantya esiphezulu ukusuka kwi-35 * 4 imibhobho ngaphezu kwamaqela amane eendlela zombhobho ecaleni kwendlela yomgca we-tangent we-stack, ukwenzela ukuba i-stack ijikeleze kwaye ihlukaniswe ngokulinganayo.Amanzi okuhlamba atshizwa ukuhlamba umphezulu we-stack, kwaye ukungcola okufakwe kwi-stack kuyatshizwa kwaye kulahlwa ngaphandle.Xa i-backwash igqityiwe, ulwalathiso lokuhamba lutshintsha kwakhona, i-laminate icinezelwe kwakhona, kwaye inkqubo iphinda ingene kwimeko yokucoca.

IParameter yobuGcisa

| Izinto zeqokobhe | umbhobho wentsimbi yeplastiki enemigca |

| Izindlu zentloko yesihluzi | inayiloni eyomeleziweyo |

| Izinto ezilaminethiweyo | PE |

| Indawo yesihluzi (i-laminated) | 0.204 square metres |

| Ukuchaneka kohluzo (um) | 5, 20, 50, 80, 100, 120, 150, 200 |

| Imilinganiselo (ubude nobubanzi) | 320mmX790mm |

| Uxinzelelo lokusebenza | 0.2MPa -- 1.0MPa |

| Uxinzelelo lwe-backwash | ≥0.15MPa |

| Isantya sokuhamba kwe-backwash | 8-18m/h |

| Ixesha lokuhlambela umva | 7 -- 20S |

| Ukusetyenziswa kwamanzi okuhlamba emva | 0.5% |

| Ubushushu bamanzi | ≤60℃ |

| Ubunzima | 9.8kg |

Iinzuzo zemveliso

I-1.I-filtration echanekileyo: Iiplati zokucoca ezichanekileyo ziyakwazi ukukhethwa ngokweemfuno zamanzi, kuquka i-20 micron, i-55 micron, i-100 micron, i-130 micron, i-200 micron, i-400 micron kunye nezinye iinkcukacha, kwaye umlinganiselo wokucoca ukhulu kune-85%.

2. Ukuhlamba i-backwashing ngokucokisekileyo kunye nokusebenza kakuhle: Ngenxa yokuba i-pores yokucoca ivuliwe ngokupheleleyo ngexesha lokuhlamba umva, kunye ne-injection ye-centrifugal, umphumo wokucoca awukwazi ukufezekiswa ngezinye izihlungi.Inkqubo yokuhlamba umva ithatha kuphela imizuzwana eyi-10 ukuya kwengama-20 ngeyunithi yokucoca.

I-3.Ukusebenza okuzenzekelayo okuzenzekelayo, ukukhutshwa kwamanzi okuqhubekayo: ixesha kunye noxinzelelo lokwahlukana kokulawulwa kwe-backwash ukuqala.Kwinkqubo yokucoca, iyunithi nganye yokucoca kunye neendawo zokusebenza zihlanjwe ngasemva ngokulandelelana.Ukutshintsha ngokuzenzekelayo phakathi kwamazwe asebenzayo kunye nokubuyisela umva kunokuqinisekisa ukukhutshwa kwamanzi okuqhubekayo, ukulahleka koxinzelelo oluphantsi lwenkqubo, kunye nomphumo wokucoca kunye nokubuyisela umva akuyi konakala ngenxa yexesha lokusetyenziswa.

I-4.Uyilo lweModyuli: Abasebenzisi banokukhetha inani leeyunithi zokucoca ezihambelanayo ngokwemfuno, eziguquguqukayo kunye neziguquguqukayo, eziguquguqukayo ezinamandla.Ukusetyenziswa okuguquguqukayo kwendawo yekona yesayithi, ngokuhambelana neemeko zendawo indawo yofakelo oluncinci.

Ukugcinwa kwe-5.Simple: phantse akukho mfuneko yokugcinwa kwansuku zonke, ukuhlolwa kunye nezixhobo ezikhethekileyo, iindawo ezimbalwa ezithintekayo.Into yokucoca i-laminated ayifuni ukutshintshwa, kwaye ubomi benkonzo bunokufikelela kwiminyaka eyi-10.

Indawo yosetyenziso

I-1.Ifayile egcweleyo okanye icwecwe elisecaleni lamanzi ajikelezayo enqaba yokupholisa: inokusombulula ngokufanelekileyo ingxaki yokujikeleza kwamanzi, ukunciphisa ukusetyenziswa kwamandla, kunye nokunciphisa umthamo, ukuthintela ukungaphumeleli kunye nokuvalwa kunye nokunciphisa iindleko zokugcinwa kwenkqubo.

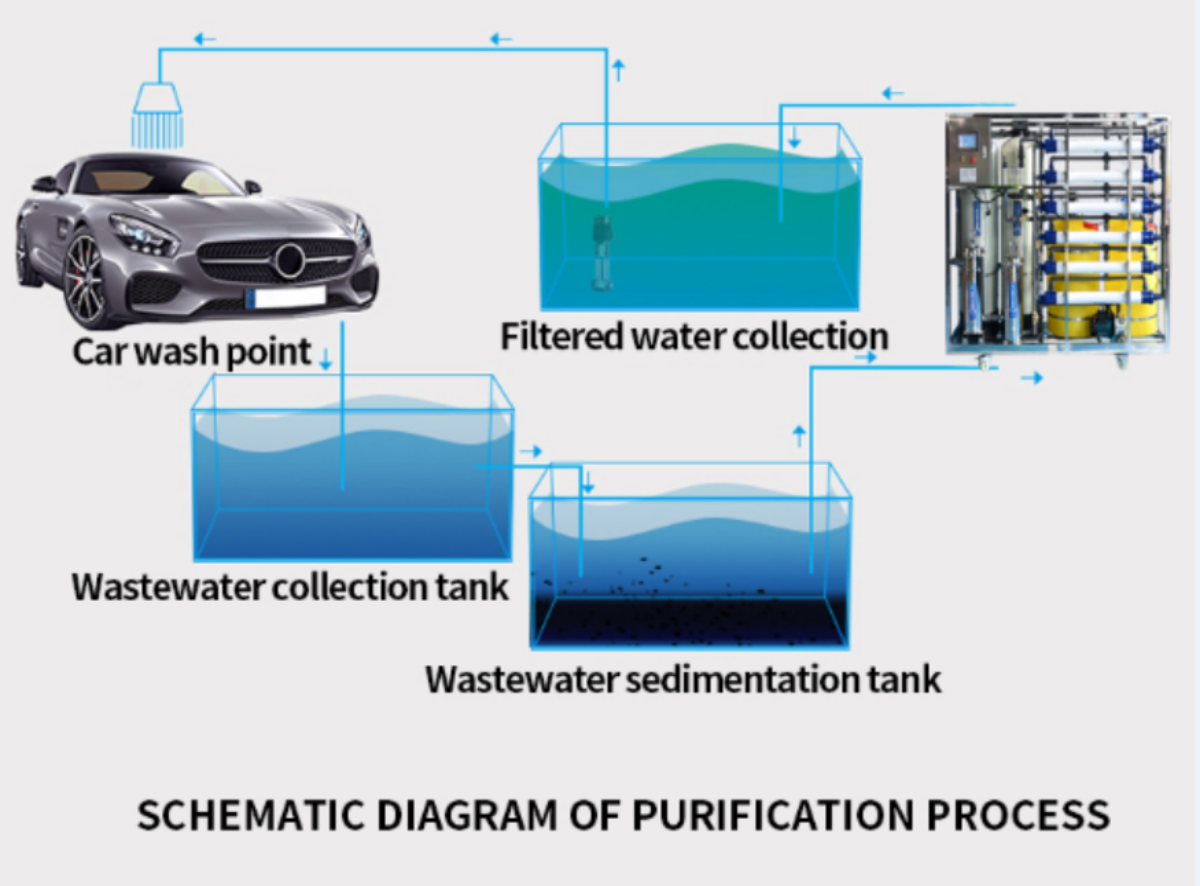

2. Ukusetyenziswa kwakhona kwamanzi abuyiselweyo kunye nokucocwa kwangaphambili kogutyulo: konga ubungakanani bamanzi ewonke, phucula umgangatho wamanzi asetyenzisiweyo, ukunciphisa okanye ukunqanda ungcoliseko olubangelwa kukukhutshelwa ngokuthe ngqo kwelindle kwindalo esingqongileyo.

3.Unyango lokukhupha ityuwa kumanzi olwandle.Ukuxhathisa ityuwa kunye nokumelana nomhlwa kwesihluzo seplastiki kungcono kunezinye izixhobo zokucoca ialloy yentsimbi ebiza kakhulu.

I-4.I-filtration yokuqala phambi kwe-ultrafiltration kunye ne-reverse osmosis unyango lwe-membrane: ukukhusela isihluzo esichanekileyo kunye nokwandisa ubomi bayo benkonzo.

Ngaphandle koko, izihluzi ezilaminethiweyo zisetyenziswa ngokubanzi: kushishino lwekhemikhali, amandla ombane, intsimbi, ukwenziwa koomatshini, ukutya nesiselo, iiplastiki, iphepha, imigodi, isinyithi, indwangu, i-petrochemical, indalo, igalufa, imoto, isihluzo sangaphambili samanzi empompo.